A Precocious Talent Earns Global Recognition

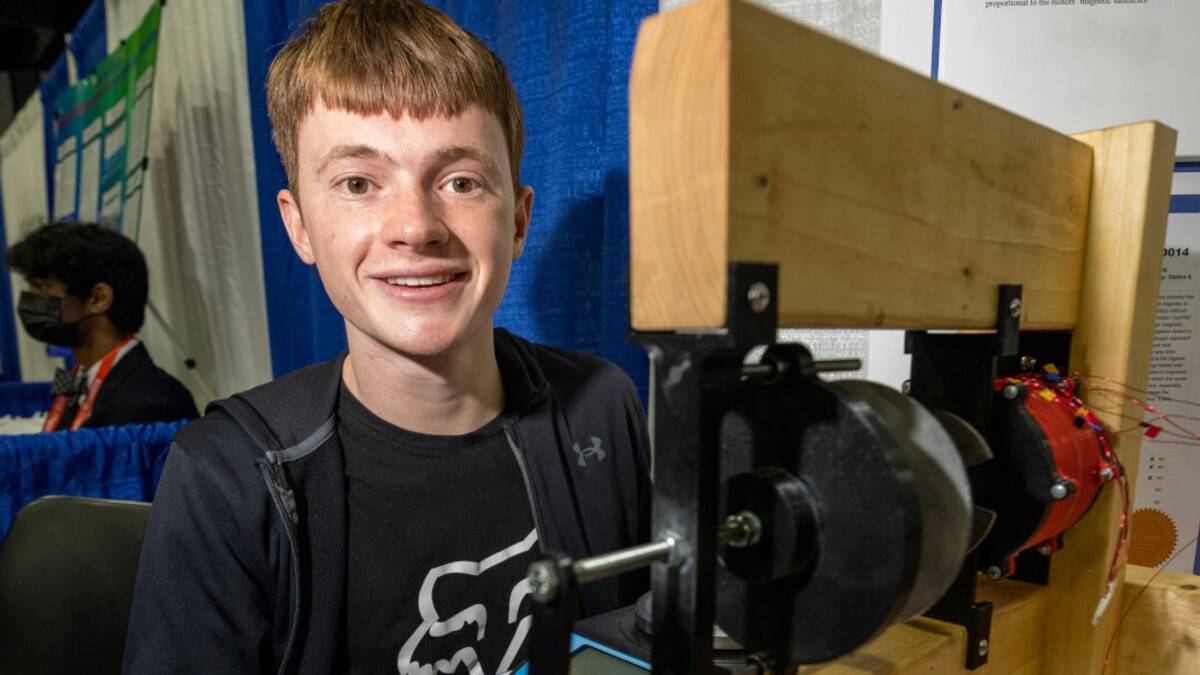

At just 17, a Florida high-school student has drawn worldwide attention for creating an electric motor that runs without rare-earth magnets. His breakthrough won first place at the Regeneron International Science and Engineering Fair 2022, the world’s premier competition for young scientists, along with a $75,000 prize.

The project caught the eye of judges and engineers not merely for cleverness, but for its potential to reshape how electric vehicles (EVs) are built and supplied.

A Simple Idea with Disruptive Potential

The teenager’s prototype is a synchronous reluctance motor—a well-known class of machines typically found in pumps and HVAC systems. What’s novel is reimagining this architecture for traction applications, where torque density, efficiency, and controllability are paramount.

Early tests suggest up to a 39% increase in torque over comparable setups, achieved without permanent magnets. For automakers battling cost curves and supply volatility, that’s a compelling signal.

Why Rare-Earth-Free Matters

Permanent-magnet motors dominate EVs because they pack high power into small packages. But they depend on rare-earth elements like neodymium and dysprosium, which come with steep costs, volatile supply, and significant environmental burdens.

Designs that remove rare-earth magnets promise multiple advantages:

- Lower material costs and reduced price volatility

- Smaller environmental footprint from mining and processing

- Greater supply-chain resilience and less dependence on single-source regions

- Easier recycling at end of life, thanks to simpler material streams

“Cutting magnets out of the equation doesn’t just change a component,” the project’s narrative suggests. “It can change the economics and ethics of electrification.”

From Garage Ingenuity to Functional Hardware

The prototype came together with a 3D printer, copper windings, and a steel rotor—a testament to resourceful engineering rather than lavish budgets. The young inventor iterated for over a year, refining geometry, laminations, and control parameters to unlock performance without exotic materials.

This isn’t a one-off success story. With more than 60 personal projects to his name—ranging from a responsive robotic hand to a go-kart that hits 110 km/h—he has a track record of building, testing, and improving. Motors fascinated him early on, especially the trade-offs surrounding magnet use, which became the spark for this research.

Industrial and Environmental Upside

If scaled, a rare-earth-free motor could deliver tangible benefits across manufacturing and policy. For industry, it points to a path of cost containment and design flexibility, especially as magnet prices swing. For governments and OEMs, it aligns with goals of localization and strategic independence, reducing reliance on a handful of countries that dominate rare-earth supply.

Equally important are the environmental gains. Rare-earth mining and processing can be energy-intensive and polluting. By sidestepping these materials, manufacturers can cut embodied emissions and reduce ecological risk—without waiting for distant upstream reforms.

The motor’s success also underscores a broader shift: continued innovation in non-magnet motor topologies. With smarter control algorithms, better materials, and improved cooling, machines like synchronous reluctance motors are increasingly competitive for traction.

What It Means for Electric Vehicles

For EV makers, the calculus is straightforward yet challenging. Permanent-magnet motors are excellent, but supply and sustainability pressures are mounting. A high-torque, rare-earth-free alternative could diversify portfolios, mitigate risk, and open new price points.

The prototype’s reported torque gains are especially promising for low- to mid-speed performance where drivers feel responsiveness most. If paired with advanced inverters and real-time control, such motors can achieve the smoothness and efficiency drivers expect—without a magnet bill of materials.

Just as crucial is manufacturability. The reliance on steel and copper—well-understood, widely available materials—could streamline scaling once designs are validated, production tooling is in place, and quality controls are established.

The Road Ahead

This achievement doesn’t end the magnet debate overnight. Commercial EV motors must juggle thermal limits, acoustic behavior, weight, efficiency across drive cycles, and strict reliability. Engineering teams will want extensive bench and road testing before moving toward production.

But the direction is clear. Inventiveness, even outside major labs, can nudge an entire industry forward. The next steps—rigorous validation, optimization under automotive standards, and potential partnerships—could bring this concept from prototype to showroom.

In an age where electrification depends on more sustainable supply chains, the idea feels both timely and inspiring. It shows that innovation is not only about better performance—it’s about building a smarter, more sustainable future for mobility.